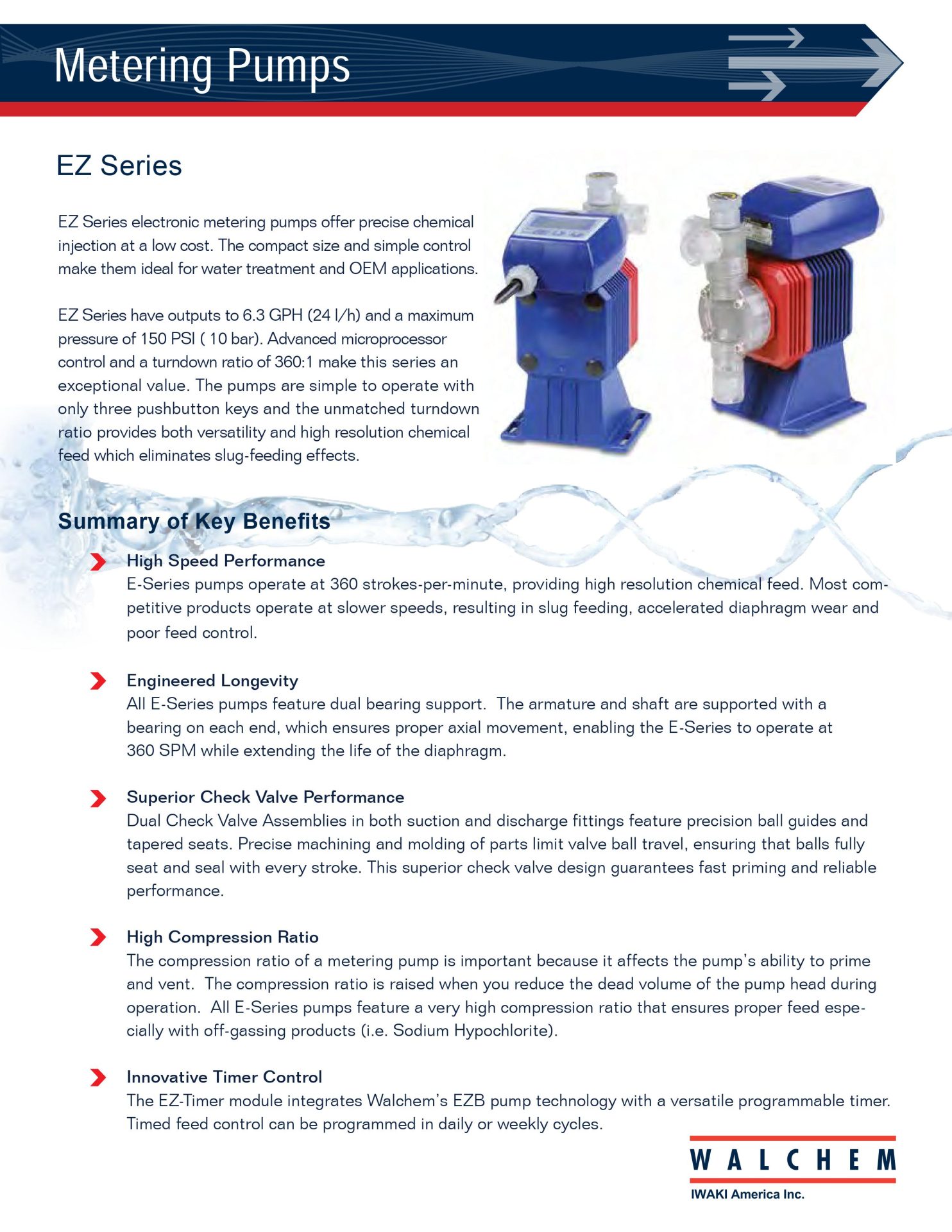

EZ Series electronic metering pumps offer precise chemical injection at a low cost. The compact size and simple control make them ideal for water treatment and OEM applications.

EZ Series have outputs of 6.3 GPH (24 l/h) and a maximum pressure of 150 PSI ( 10 bar). Advanced microprocessor control and a turndown ratio of 360:1 make this series an exceptional value. The pumps are simple to operate with only three pushbutton keys and the unmatched turndown ratio provides both versatility and high-resolution chemical feed which eliminates slug-feeding effects.

High Speed Performance

E-Series pumps operate at 360 strokes-per-minute, providing high resolution chemical feed. Most competitive products operate at slower speeds, resulting in slug feeding, accelerated diaphragm wear and poor feed control.

Engineered Longevity

All E-Series pumps feature dual bearing support. The armature and shaft are supported with a

bearing on each end, which ensures proper axial movement, enabling the E-Series to operate at

360 SPM while extending the life of the diaphragm.

Superior Check Valve Performance

Dual Check Valve Assemblies in both suction and discharge fittings feature precision ball guides and

tapered seats. Precise machining and molding of parts limit valve ball travel, ensuring that balls fully

seat and seal with every stroke. This superior check valve design guarantees fast priming and reliable

performance.

High Compression Ratio

The compression ratio of a metering pump is important because it affects the pump’s ability to prime

and vent. The compression ratio is raised when you reduce the dead volume of the pump head during operation. All E-Series pumps feature a very high compression ratio that ensures proper feed especially with off-gassing products (i.e. Sodium Hypochlorite).

Innovative Timer Control

The EZ-Timer module integrates EZB pump technology with a versatile programmable timer.

Timed feed control can be programmed in daily or weekly cycles.

The EZ series electronic metering pumps consist of a pump unit, a drive unit, and a control unit. The drive unit is an electromagnetic solenoid. When the solenoid coil is energized by the control unit the armature shaft moves forward due to the magnetic force of the solenoid. The shaft is attached to a PTFE faced diaphragm which is part of the pump unit. The diaphragm is forced into the pump head cavity decreasing volume and increasing pressure which forces liquid in the pump head out through the discharge check valves. When the solenoid coil is de-energized, a spring returns the armature to its starting position. This action pulls the diaphragm out of the head cavity increasing volume and decreasing pressure. Atmospheric pressure then pushes liquid from the supply tank through the suction check valves to refill the pump head.