ROBOT COVERS

+ TEXTILES

Dimachem is proudly the Canadian distributor for BWI.

Our manufacturing plant is in Gas City Indiana and is a 50% Canadian owned company.

Since 1979, OEM paint facilities using robotics for topcoat systems application of prime, base, clear and related coatings have utilized BWI robot masking covers. Why?

- Paint overspray accumulation barrier

- Paint drip or flake contamination prevention

- Extended production uptime and process reliability

- Reduced V.O.C cleaning solvent consumption

- Optimized equipment longevity

- Rapid system cleaning and return to production

BWI CAD designs and manufactures custom, Cleanroom prepared automation covers from a variety of materials, selected for optimized performance features, including;

- Paint absorbency and barrier

- Robot spray path flexibility

- Secure fitment

- Low-lint characteristics

- Simple installation

- Rapid replacement

Brands We Serve

BWI award winning products and services support a variety of industries including Aerospace, Agriculture, Aircraft, Appliance, Automotive, Biotech, Cabinet, Commercial Trailer, Eyeglass, Fascia, Heavy Duty Truck, Micro-Electronics, Motorcycle, Musical Instrument, Pharmaceutical, Power Tools and more.

World Class Automotive OEM Paint Finishing Facilities makeup the largest portion of BWI customers, requiring significant process knowledge and a highly skilled workforce.

It Starts with Design

The Right Skills, The Right Tools

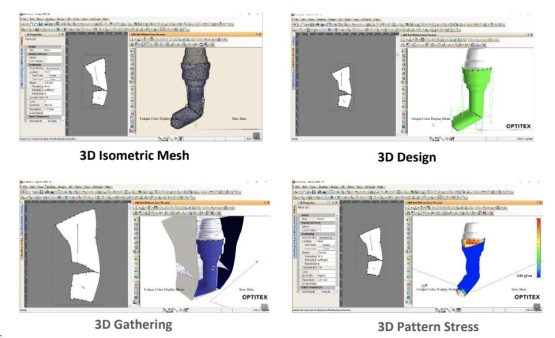

BWI utilizes Gerber Technology AccuMark® and efi® OptiTex 2D and 3D PDS systems for optimized pattern design. These systems represent the most advanced CAD technology available in the apparel industry, used by the most iconic worldwide clothing brands.

BWI field technicians and in-house R&D staff collaborate to optimize pattern features for customer equipment fitment, reliability, ease of installation and lowest cost.

Decades of collective design and process knowledge go into every pattern we make, start to finish!

Cut to Perfection

Digitized Pattern Nest and Cut

Upon sample approval, customer parts are rapidly streamlined into production by use of the most advanced plotting and cutting systems available in the textile industry.

Cleanroom Suites

System Contamination Prevention

Dimachem cleanroom suites are ISO class 4 and 5